Industrial Applications

Industrial sensors are used in a variety of applications where the consistent measurement of gases is required to monitor or control industrial processes.

- Gas measurement ranges from 0 ppm to 100%

- 24VDC and 4-20mA industry standard outputs

- Serial UART and RS485 output options

- Wide temperature ranges from -100C up to 700C

- Rugged aluminum and steel housings

Oxygen Generation

Oxygen Generation systems that produce up to 100% oxygen need 0-100% oxygen sensors and the ability to communicate with a wide variety of equipment. We suggest the SST Zirconia Sensor Oxygen measurement system. Zirconia oxygen sensors are stable, reliable, have a long life and can measure up to 100% oxygen depending on the board and sensor combination used. For the fastest speed and highest accuracy, consider the TS-404 TecMicro Oxygen Sensor.

During oxygen generation, a buildup of oxygen can result in a potential fire hazard. We also recommend an Oxygen Enrichment Safety Alarm in the same room with the oxygen generator.

Chemical Processing

Bulk tanks of hydrogen, oxygen, carbon dioxide and carbon monoxide and more are critical inputs to dozens of industrial chemical processes. Hydrogen is a key feedstock in the petrochemical industry, while oxygen is used in coal gasification.

For industrial chemical processing applications the TX 25% Oxygen Industrial Sensor is designed to measure 0-25% oxygen levels. The optical oxygen sensor has a RS485 Modbus RTU interface, industry-standard 4-20mA analog output, and can use 6V-24VDC power.

Boiler and Exhaust Flue Stack Gases

Measuring oxygen levels in exhaust gases is critical for maximizing fuel use during combustion and to limit harmful gases being exhausted. Oxygen sensors in a flue stack must be rugged and capable of working in high temperature environments. For example, the Oxy-Flex Oxygen Analyzer can measure the oxygen concentration in air or gas mixtures with temperatures of -100 to 400⁰C. The OXY-GAP-100 Gas Analyzer monitors the oxygen content within flue or stack gases up to 700⁰C making it a complete solution for combustion optimization for boiler trim applications.

Welding

Shielding gases are required for high quality MIG, TIG and MAG welding of stainless steel, low alloy steel, aluminum, nickel alloy, copper alloys, and others. The most common shielding gas argon is used to purge oxygen from the weld to protect from melting defects, porosity and the formation of slag. and also of hard residues that are formed from the flux after welding.

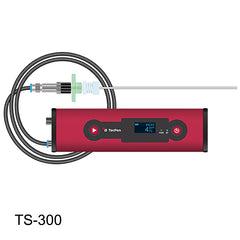

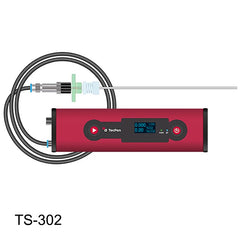

To verify oxygen levels are at or near 0 parts per million the TecPen Weld Purge Monitor uses a precision oxygen sensor in a convenient hand-held device.

Petrochemical

In the petrochemical industry oxygen is used for oxidation of raw chemicals for recovery of nitric acid, ethylene oxide, propylene oxide, vinyl chloride and other chemical compounds. In the oil and gas industry, oxygen is used to boost production in oil cracking plants and for the reduction of sulfuric deposits in refineries.

SST Sensing's Zirconia Sensor Oxygen Measurement System offers a complete oxygen level measurement solution removing the need for customers to develop their own electronics. It can be used in combustion control systems for coal, oil or gas systems.

Industrial Cryogenic Processing

Cryogenic gases like argon, helium, hydrogen, nitrogen, oxygen, methane and CO2 are all useful because of their very low temperatures when stored under pressure as liquids. Cryogens are used in many industrial applications including:

- Flash-freezing food

- Superconductivity

- Rocket launcher propulsion

- Cryogenic cleaning

- Cryo grinding

- Reactor cooling

All cryogenic gases are asphyxiates except for oxygen. For worker safety around cryogenic liquids, industrial facilities depend on personal oxygen safety monitors or oxygen deficiency alarms.